Using Microcontroller Development Boards as Single Board Computers

Contributed By DigiKey's North American Editors

2020-07-29

Semiconductor suppliers support their microcontrollers with development boards, such as evaluation and demo boards. The intended use for these boards is so engineers can first become familiar with the target microcontroller, and second to assist in microcontroller hardware and firmware development. These boards range from the simplest with general purpose input/output (GPIO) made available by header connectors, to sophisticated boards with keypads and LCD displays. With the wide variety of such development boards available, some engineers are selecting these boards for volume purchase for use in industrial applications.

However, unlike industrial quality single board computers (SBCs), development boards are often not subjected to rigorous manufacturer quality assurance (QA) testing in order to guarantee operation for continuous use under industrial conditions. Development boards typically undergo QA only at room temperature and at low humidity. This brings up questions of reliability and suitability for a continuous use application. While development boards still use QA tested semiconductor and hardware components intended and tested for commercial or industrial use, engineers need to understand how development boards are specified differently than industrial SBCs, and what level of testing the engineer should do before approving a board for continuous use.

To address these issues, this article will discuss the limitations of these boards, how to properly determine their suitability for the target application, and what issues an engineer needs to consider when selecting a development board for continuous application use. It then examines two development boards from STMicroelectronics and Infineon Technologies and discusses how they may be applicable for a continuous use application.

Industrial SBC quality assurance

Off-the-shelf industrial SBCs are the most popular way of controlling industrial electromechanical equipment, as well as managing Internet of Things (IoT) and Industrial IoT (IIoT) nodes. An SBC is already populated with tested components and comes with complete documentation for use. A custom designed SBC is an option if the volume is high enough and no off-the-shelf SBC provides the needed functionality at the proper price point. However, an already tested off-the-shelf solution can still be superior to a custom SBC in that it provides for faster development and time to market.

Manufacturers of SBCs subject new boards to a long series of harsh quality control tests before releasing the design for production. SBCs specifically designed for industrial use undergo rigorous quality control testing to ensure they can operate reliably in the target application. For a common industrial application rated at -40°C to +85°C, industrial grade semiconductors and hardware that are rated over temperature are selected. The components are mounted on a pc board with material that also operates over the rated temperature range. For some applications, conformal coating may be applied over the SBC to protect the board against humidity, dust, and ambient particles, as well as chemical spills.

Initial QA of a new industrial SBC includes bench testing the upper and lower electric rating limits of current and voltage. After this basic testing, the new SBC then undergoes a full and lengthy QA and is tested for full operation under the target temperature extremes of heat and cold, as well as the extremes of humidity and vibration. The manufacturer of the new industrial SBC can also conduct stress tests where it is tested for days under extreme conditions. Any failure, no matter how small, is logged and diligently tracked to its cause. Test failures can result in components being replaced or the SBC redesigned. QA testing can take weeks or months. Only when the SBC design has been fully qualified does the manufacturer finally release the board to production. Each individual SBC now in production undergoes quick tests at the end of the production line that usually take less than a minute.

Even after releasing the SBC to production, testing doesn’t stop. The manufacturer of the industrial SBC may randomly pull an SBC off production and subject it to a full QA on a quarterly or yearly basis to ensure that quality is being maintained.

Often these QA results are available to customers. In addition, the SBC manufacturer will send an engineering change notice (ECN) to SBC customers on any change such as whenever board components are replaced.

Microcontroller development boards

Development boards used to support microcontrollers are provided by both microcontroller manufacturers as well as by third-party tool providers. Evaluation boards are simple boards used to study the microcontroller in general and examine basic operation. Demonstration, or more popularly “demo” boards, demonstrate the microcontroller operation and are often more sophisticated with blinking LEDs, switches, and an LCD display. Development boards are used for hardware and firmware development.

In reality the names evaluation, demo, and development are not standardized and the board target usage greatly overlaps. The name of the board is less important than its features, and it’s easier and less confusing to just lump all the boards together under the term “development boards.”

Development board testing for industrial use

The development boards released by microcontroller manufacturers or supplied by third parties undergo less stringent testing than industrial SBCs. Components are usually commercial grade, but some boards include industrial grade components. Development boards are designed to operate under room temperature only. First prototypes of development boards will undergo room temperature testing for days or weeks, but this varies greatly based on the manufacturer. The only target quality requirement for development boards is that they operate over room temperature. It’s safe to assume that the board hasn’t been tested over temperature extremes, in high humidity, or under vibration or shock conditions.

The prime objective when determining what development board to use in an industrial application is to reduce risk. For that reason, it’s important to first look at the board manufacturer—specifically, the manufacturer’s end-of-life (EOL) policy and history for development boards. The last thing an engineer needs is for volume purchasing of the perfect board only for it to be discontinued because of an EOL. If the manufacturer has a history of maintaining production of development boards, it can be safe to source from them. But if the manufacturer has a history of regularly discontinuing such boards, sourcing one is too risky.

When deciding whether or not to use a development board in an industrial application, look at the components on the board; ensure that the components are of the proper temperature grade for the target application. If the board is to inhabit an industrial environment alongside human operators, then commercial grade components are probably adequate for the application. Any connectors or other associated hardware parts should be examined to make sure they are mounted firmly. Any screws not soldered in should be given a gentle test turn with a screwdriver—too much play is a warning and can indicate an inconsistent QA process.

If board components and construction are acceptable, then it’s a good idea to simultaneously stress test three or more boards under high temperature for a period of days. To get a good idea of production consistency, each test board should be purchased separately over time so that different board production lots are sampled. Any failure is bad, and unless the manufacturer can adequately explain the failure as an exception, then a different development board should be selected.

If the board is to be used in a high humidity environment, then the board should be tested in an environment of appropriate humidity. Development boards are not designed for high humidity use. Conformal coating can be applied to the pc board to protect against humidity, provided that connectors and electrical contact points are carefully protected from the coating.

Also check with the manufacturer to see if they send an ECN with every change on the board. Often this is not done with development boards, so to be safe, all incoming purchased boards should be visually verified for changes in components.

If the board is to be used in a high vibration environment, then it should be mounted in a test frame and vibration tested. At the end of the test it should be visually examined for cracks or deformities. Screws and tabbed mountings should be checked for play. Any failure or defect is bad and should remove that board from consideration.

Development board for continuous use

Following are two examples of development boards that may be suitable for continuous use industrial applications. The manufacturers did not certify these boards for continuous industrial use: it is up to the engineer to do their own testing to qualify a board for a particular end application.

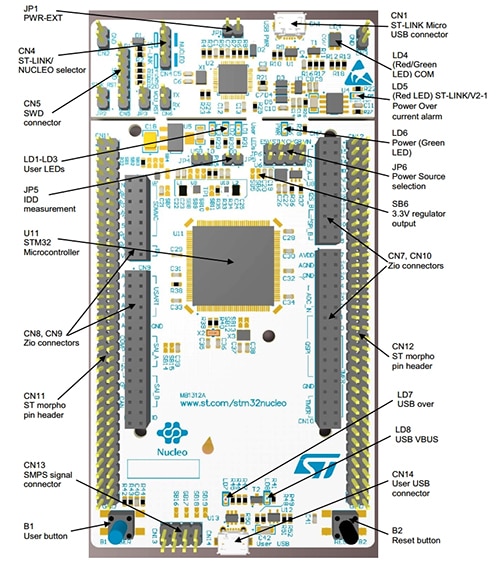

The popular Arduino form factor has resulted in many derivatives of the board from manufacturers. For example, the NUCLEO-L4P5ZG from STMicroelectronics is based on an Arm® Cortex®-M4 microcontroller. An overview of the board layout shows its many features (Figure 1). The NUCLEO-L4P5ZG has a set of header connectors that makes all of the microcontroller’s GPIO available to the application.

Figure 1: The STMicroelectronics NUCLEO-L4P5ZG is an Arduino-compatible Nucleo board with basic development board functionality that pulls all GPIO pins out to header connectors. It has three user-programmable LEDs, a user pushbutton, and a reset button. (Image source: STMicroelectronics)

Figure 1: The STMicroelectronics NUCLEO-L4P5ZG is an Arduino-compatible Nucleo board with basic development board functionality that pulls all GPIO pins out to header connectors. It has three user-programmable LEDs, a user pushbutton, and a reset button. (Image source: STMicroelectronics)

An important advantage of the NUCLEO-L4P5ZG is that the GPIOs are compatible with many of STMicroelectronics’ Nucleo line of Arduino-compatible boards. This means compatible Nucleo second-source replacements are available in case of product discontinuance. The board has three LEDs and a pushbutton that are under firmware control, as well as a hardwired reset button. The LEDs can show simple status, and a hard reset button allows the board to quickly recover from firmware lockups. It has a USB On-The-Go (OTG) Full Speed connector under firmware control and a micro USB connector for programming and debugging. The white pc board makes it easier to shed heat in warm environments. The NUCLEO-L4P5ZG is suitable for applications where I/O needs to be managed such as with sensors, switches, and actuators.

Another example of a development board for possible application use is the Infineon Technologies KITXMC47RELAXV1TOBO1 Relax Kit. It is also based on an Arm Cortex-M4 and has a full set of Arduino pads without the header connectors (Figure 2). The Relax Kit is a good choice for a networked application or a basic IIoT node with an RJ45 connector for Ethernet networking. It has two pushbuttons and two LEDs under firmware control, and a reset button.

Figure 2: The Infineon Technologies KITXMC47RELAXV1TOBO1 Relax Kit has all the GPIO pulled out to pc board contact holes. It supports serial interfacing using available Ethernet and USB connectors, and can expand memory using a microSD card slot. (Image source: Infineon Technologies)

Figure 2: The Infineon Technologies KITXMC47RELAXV1TOBO1 Relax Kit has all the GPIO pulled out to pc board contact holes. It supports serial interfacing using available Ethernet and USB connectors, and can expand memory using a microSD card slot. (Image source: Infineon Technologies)

The Infineon Relax Kit also has a microSD card slot. This makes it easy to change firmware or application data for different boards by just swapping in a different microSD flash memory card. The kit is suitable for rugged networked applications that need to monitor sensors, switches, and control actuators, and the microSD card is useful where firmware or data changes happen regularly and is more efficient than reprogramming the board.

Conclusion

Microcontroller development boards may be used as industrial application boards if the board is carefully chosen and tested before being put to use in the target application. The engineer needs to do rigorous testing of the hardware before use, and carefully check the manufacturer for supply reliability including EOL policies. With the huge selection of development boards available, an engineer can easily find a board that passes internal QA for use in an industrial application.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.